?????? 佛塑科技錨定“雙碳”目標、把握“雙碳”契機,積極推動生產制造向綠色低碳轉型升級,加大綠色發展的投入力度并貫穿生產經營全過程,爭當綠色低碳的實踐者、推動者,助力“雙碳”目標的實現。

?

?????? 以清潔生產為抓手??提升綠色制造水平

?????? 佛(fo)塑科技以(yi)深(shen)入開(kai)展(zhan)(zhan)清(qing)潔(jie)(jie)生(sheng)產(chan)(chan)(chan)審核(he)為(wei)抓手,樹立綠(lv)色(se)(se)(se)(se)(se)發(fa)展(zhan)(zhan)理(li)(li)念,促進(jin)公(gong)(gong)司(si)(si)向綠(lv)色(se)(se)(se)(se)(se)制(zhi)(zhi)造轉型。結(jie)合“十四(si)五”發(fa)展(zhan)(zhan)規(gui)劃,扎實做(zuo)好綠(lv)色(se)(se)(se)(se)(se)制(zhi)(zhi)造體系的建(jian)設工(gong)(gong)作(zuo)(zuo),提升綠(lv)色(se)(se)(se)(se)(se)制(zhi)(zhi)造水(shui)平,打造綠(lv)色(se)(se)(se)(se)(se)清(qing)潔(jie)(jie)生(sheng)產(chan)(chan)(chan)企(qi)(qi)業,生(sheng)產(chan)(chan)(chan)管(guan)(guan)理(li)(li)全流程以(yi)綠(lv)色(se)(se)(se)(se)(se)工(gong)(gong)廠(chang)的標準為(wei)導向,制(zhi)(zhi)定“綠(lv)色(se)(se)(se)(se)(se)工(gong)(gong)廠(chang)”創建(jian)工(gong)(gong)作(zuo)(zuo)方案及“綠(lv)色(se)(se)(se)(se)(se)工(gong)(gong)廠(chang)”中(zhong)(zhong)長(chang)(chang)期規(gui)劃,開(kai)展(zhan)(zhan)“綠(lv)色(se)(se)(se)(se)(se)工(gong)(gong)廠(chang)”評價,創建(jian)適合企(qi)(qi)業綠(lv)色(se)(se)(se)(se)(se)持續發(fa)展(zhan)(zhan)長(chang)(chang)效(xiao)機制(zhi)(zhi)。同時,響����應雙(shuang)碳(tan)新要求,識別重點碳(tan)排領(ling)域和(he)工(gong)(gong)藝(yi),開(kai)展(zhan)(zhan)碳(tan)排放核(he)查工(gong)(gong)作(zuo)(zuo),并委(wei)托(tuo)第三方開(kai)展(zhan)(zhan)碳(tan)核(he)查,摸(mo)清(qing)家(jia)底,為(wei)公(gong)(gong)司(si)(si)領(ling)導決策提供支撐;積極(ji)開(kai)展(zhan)(zhan)BOPA產(chan)(chan)(chan)品(pin)生(sheng)命(ming)周期和(he)產(chan)(chan)(chan)品(pin)碳(tan)足(zu)跡工(gong)(gong)作(zuo)(zuo),完善綠(lv)色(se)(se)(se)(se)(se)供應鏈(lian)的管(guan)(guan)理(li)(li)要求,助力優化產(chan)(chan)(chan)品(pin)及供應鏈(lian)全生(sheng)命(ming)周期的管(guan)(guan)理(li)(li)。公(gong)(gong)司(si)(si)現共有4家(jia)分公(gong)(gong)司(si)(si)、6家(jia)控(kong)股子公(gong)(gong)司(si)(si)通過了清(qing)潔(jie)(jie)生(sheng)產(chan)(chan)(chan)審核(he),其(qi)中(zhong)(zhong),公(gong)(gong)司(si)(si)下屬東方電(dian)工(gong)(gong)膜分公(gong)(gong)司(si)(si)和(he)東方包裝膜分公(gong)(gong)司(si)(si)獲評省級清(qing)潔(jie)(jie)生(sheng)產(chan)(chan)(chan)企(qi)(qi)業。

?

??????? 提升標準管控水平??賦能低碳轉型

?

?????? 佛塑科技(ji)積極(ji)開(kai)展質(zhi)量(liang)管(guan)(guan)(guan)理(li)體系、環(huan)境(jing)管(guan)(guan)(guan)理(li)體系、能源管(guan)(guan)(guan)理(li)體系、職(zhi)業(ye)(ye)健康安(an)全管(guan)(guan)(guan)理(li)體系和相關計量(liang)體系等標準認(ren)證。通(tong)過(guo)體系的建立、實施、保持和持續(xu)改進(jin),不斷提升綜合(he)管(guan)(guan)(guan)理(li)水平,從而(er)推動生產管(guan)(guan)(guan)理(li)各項工作提質(zhi)增效,為公(gong)(gong)(gong)司(si)(si)高質(zhi)量(liang)發展提供有力支撐。目前(qian),共有6家(jia)分公(gong)(gong)(gong)司(si)(si)和8家(jia)控股(gu)子公(gong)(gong)(gong)司(si)(si)通(tong)過(guo)ISO14001環(huan)保管(guan)(guan)(guan)理(li)體系認(ren)證,6家(jia)分公(gong)(gong)(gong)司(si)(si)和2家(jia)控股(gu)子公(gong)(gong)(gong)司(si)(si)通(tong)過(guo)IS045001職(zhi)業(ye)(ye)健康安(an)全管(guan)(guan)(guan)理(li)體系認(ren)證,5家(jia)分公(gong)(gong)(gong)司(si)(si)通(tong)過(guo)了ISO50001��������能源管(guan)(guan)(gu����an)理(li)體系認(ren)證。

?????? 佛塑(su)科技(ji)建立節(jie)(jie)能(neng)(neng)減排(pai)理(li)念,積極開展節(jie)(jie)能(neng)(neng)改造,推動實施多項(xiang)(xiang)技(ji)術改造項(xiang)(xiang)目,提(ti)升設備性能(neng)(neng),提(ti)高能(neng)(neng)效(xi������ao)水平,降低(di)單位產品能(neng)(neng)耗(hao),形成節(jie)(jie)能(neng)(neng)減排(pai)的自律機(ji)制。緯達公司和經緯分公司分別開展數字化(hua)工廠標(biao)桿建設和智能(neng)(neng)工廠改造試點,通過綠色節(jie)(jie)能(neng)(neng)、減排(pai)、降耗(hao)、技(ji)術創新、生產智能(neng)(neng)化(hua)數字化(hua)等手(shou)段,賦(fu)能(neng)(neng)生產過程控制,降低(di)能(neng)(neng)耗(hao)物耗(hao),減少(shao)能(neng)(neng)源浪費,減少(shao)無效(xiao)碳排(pai)放(fang),實現生產潔凈化(hua)、廢(fei)物資源化(hua),助力實現公司節(jie)(jie)能(neng)(neng)低(di)碳高質量發展。2022年(nian)佛塑(su)科技(ji)獲(huo)評佛山市節(jie)(jie)水型企(qi)業。

?

?????? 加大綠色能源項目建設??助力節能降碳

?

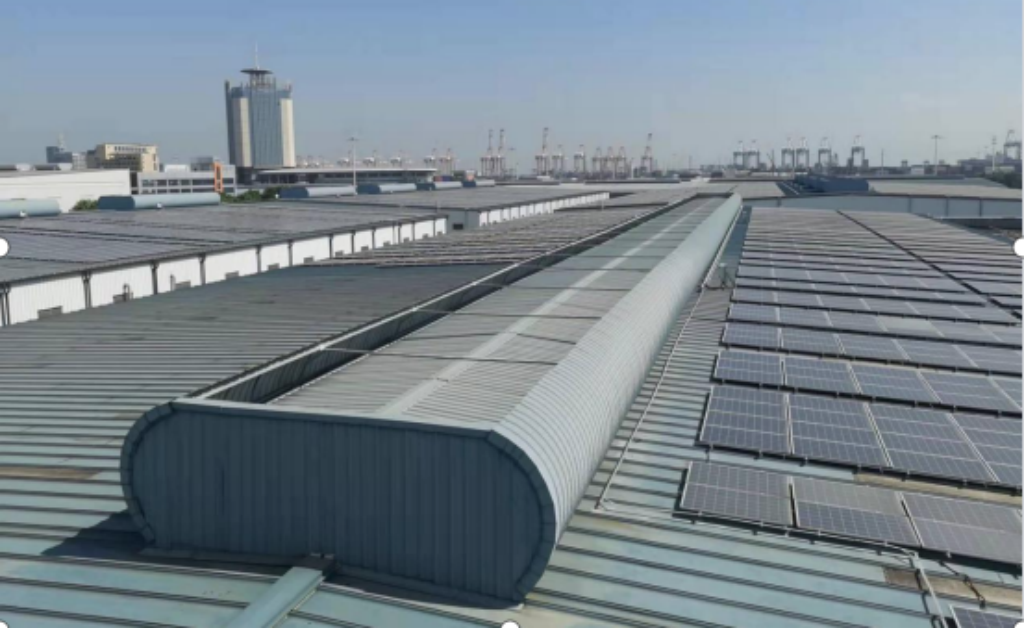

???? ? 光伏項(xiang)目不(bu)僅能有效隔熱,還能減少溫(wen)室(shi)(shi)氣體(ti)及(ji)其它有害氣體(ti)的排放。項(������xiang)目建成后,能有效降低室(shi)(shi)內溫(wen)度3-6℃,提高廠房(fang)內舒適度,降低空調能耗,緩解夏(xia)季錯峰用電(dian),減輕變(bian)壓(ya)器負(fu)荷量(liang)。

?????? 佛(fo)(fo)塑科技加快光(guang)(guang)伏(fu)(fu)一體(ti)化(hua)(hua)項(xiang)目(mu)(mu)建設,促進低碳(tan)清潔能源的使(shi)用(yong)。公司下(xia)屬3家控股企(qi)業結合自(zi)身實(shi)際開(kai)展光(gua�����ng)(guang)伏(fu)(fu)發電(dian)(dian)項(xiang)目(mu)(mu),率(lv)先實(shi)現光(guang)(guang)伏(fu)(fu)發電(dian)(dian)與普通(tong)用(yong)電(dian)(dian)的無縫轉換應用(yong)。截至目(mu)(mu)前(qian),合捷公司光(guang)(guang)伏(fu)(fu)用(yong)電(dian)(dian)占總用(yong)電(dian)(dian)的34.8%,金萬達公司及三水(shui)順(shun)通(tong)公司光(guang)(guang)伏(fu)(fu)用(yong)電(dian)(dian)占總用(yong)電(dian)(dian)的30%,華(hua)韓、緯達、三水(shui)東(dong)電(dian)(dian)等企(qi)業正全面推進屋頂光(guang)(guang)伏(fu)(fu)發電(dian)(dian)項(xiang)目(mu)(mu)。佛(fo)(fo)塑科技通(tong)過(guo)開(kai)展光(guang)(guang)伏(fu)(fu)發電(dian)(dian)項(xiang)目(mu)(mu),實(shi)現每年節能1091噸標煤,減少(shao)二氧(yang)化(hua)(hua)碳(tan)排放約2973噸,有效減少(shao)常(chang)規能源的消耗,促進節能減排。

?▲合(he)捷公司光(guang)伏發(fa)電(dian)應用

?

?????? 加大污染治理力度??推進減污降碳協同增效

?

?????? 佛塑科�������技不斷(duan)加大污染治(zhi)(zhi)(zhi)理(li)投入,逐步(bu)淘汰(tai)低效治(zhi)(zhi)(zhi)理(li)工藝,對治(zhi)(zhi)(zhi)理(li)設施進行升級改造,持續(xu)改善環(huan)境質量。

?????? 一是加大(da)���(da)有機廢(fei)氣治理設(she)施技(ji)改,著力(li)科學(xue)治污,加大(da)(da)有機污染(r�����an)物的減排力(li)度,打好污染(ran)防治攻(gong)堅戰。

?????? 二是開展源頭������結構調整、污(wu)染治理(li)和全過程精細化(hua)管理(li),通(tong)過集氣系(xi)統改������造,加大廢氣收(shou)集效率(lv),減少污(wu)染物無組織排放。

?????? 三是推進VOCs和(he)O?�����等多污染物、多污染源(yuan)協(xie�����)同控制協(xie)同減排。

?????? 四(si)是進一(yi)步推(tui)進燃氣鍋爐低氮(dan)燃燒改造項目,通(tong)過������更換(huan)低氮(dan)高能效鍋爐(熱(re)風型)和(he)更換(huan)低氮(dan)燃燒器等方式,降低氮(dan)����氧化物的排放濃度及總量。

▲有機廢氣治理設施

??????

?????? 強化綠色宣傳培訓??提升綠色發展意識

?????? 佛塑科技積極組織(zhi)������開展《綠色(se)制造體系建設》及“雙碳(t������an)”知識(shi)專項培訓,提升全(quan)員綠色(se)發展意識(shi),加強人才隊伍建設,把綠色(se)理念轉(zhuan)化(hua)為(wei)員工的(de)具體行動中、融入生產流程中。同時,佛塑科技推進節能減(jian)污、低碳(tan)行動的(de)宣(xuan)(xuan)傳(chuan)工作(zuo),廣(guang)泛開展形式多樣的(de)宣(xuan)(xuan)傳(chuan)活動,營造良(liang)好的(de)宣(xuan)(xuan)傳(chuan)氛圍。

▲“雙碳”知識學習和培訓

?????? 接(jie)下(xia)來,佛(fo)塑科技將持(chi)續(xu)圍繞綠色(se)發(fa)展(zhan),減污降碳要求,積極向綠色(se)低碳制(zhi)造(zao)轉(zhuan)型(xing)升級,堅定(ding)不移走綠色(se)可持(chi)續(xu)發(fa)展(zhan�������������)之路,積極推進(jin)實現“雙碳”目標。

?